There are some countries in the world that will actually chop down trees for the express purpose of converting that material into charcoal. It is a large business, one that is responsible for devastating thousands of acres of pristine forest. Fortunately, there is a better way to create charcoal. Instead of using living trees, you can use rubber tires, plastic, and even the residue from harvesting crops as a source material. To convert this material into charcoal, you will need a pyrolysis machine, or in some cases, an entire pyrolysis plant to get the job done. To find the best wood charcoal making machine that is currently on the market, there are some strategies you can use to find it and also obtain it for a good price.

How Can Machines Convert Organic Material Into Charcoal?

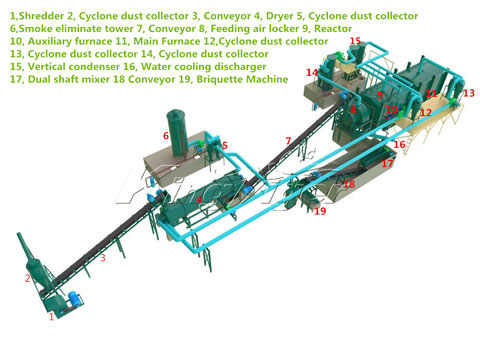

Whether you are harvesting rice, coconuts, or other commodities that are grown, there is often residual organic material. The coconut shells, rice husks, and even what remains after a bamboo harvest, can be put into these machines and converted into charcoal. To ensure that the final product will burn, and that the process can happen at all, oxygen is removed from the reactor where this material is placed. The air is sucked out, and the heat is increased inside, allowing the organic material to chemically change into different byproducts: https://kingtigergroup.com/sawdust-briquette-charcoal-making-machine/.

What Are The Byproducts Of This Pyrolysis Process?

The byproducts are going to be a type of diesel fuel called biofuel. It will work just the same. You will also have bio oil which can be used for lubricating metal components, or it can be utilized by people that are looking for certain cosmetic products. Finally, there is the charcoal aspect of this business which is quite lucrative. As mentioned before, there are people that will work so hard to chop down trees just to make charcoal that they can sell. Instead, by accessing landfills that might be nearby, they can make charcoal from biomass, and any other organic waste by using these machines regularly.

How These Machines Can Literally Change The Landscape Of Communities

Using that same example, instead of chopping down the forest to make charcoal, you could actually employ people to operate these pyrolysis machines and plants. By doing so, you are removing the waste products from the ground, and also creating charcoal that people will use and burn. It is a win-win scenario for many communities, which is why some companies in China are expanding into areas like South Africa where the quantity of rubber tires and plastic is out of control. They are able to use these byproducts from the pyrolysis process to also help keep the community warm.

Our company: https://www.environmental-expert.com/companies/kingtiger-shanghai-environmental-technology-co-ltd-97695.