There are lots of waste crop stalks in the world, such as the peanut stalks, cornstalk, straws and so on. How to efficiently recycle those waste to energy, and make them harmless to the environment is a task of top priority, and the charcoal machine is a new trend. The plant can convert the biomass waste to charcoal, whose carbon content is much higher than the common carbon.

Wide Application of the Biomass Charcoal

We all know that the biomass carbon has huge market demand, but many of us only know that the carbon can be used as fuel, and they have no idea about the other use of the biomass, here we will list you some.

First, the carbon can be used to heat, and it is also the first choice to food industry, because of the high heating power, long burning time and smokeless combustion.

Second, there are many small holes in the carbon, so it has a great adsorptivity, so it can be used as dehumidizer, especially coconut shell charcoal, which can absorb the moisture in the air, and when the room is dry, it can also release the moisture, in this way, it can control the humidity. That’s why coconut shell charcoal making machine is a very good investment option.

Third, it can improve the soil quality, and create a good environment for the plants, so it can be widely used in agriculture and gardening.

Fourth, thanks to its adsorptivity, it can remove the harmful material in the air, so if you have a newly decorated house, you can use it to keep yourself and your family safe.

Fifth, the biomass carbon can be used as a deodorant and help you store the food.

Sixth, the carbon can also be the raw material for making maquillage.

The straw charcoal machine for sale is equipped with the automatic temperature control device, so during the working process, it can monitor the temperature and ensure the safety and quality. The carbonization temperature can reach 800-1000℃, and the electric control cabinet can regulate the temperature, so controlling the temperature can also ensure that the plant can work in a continuous way. More information on biochar production equipment for sale here.

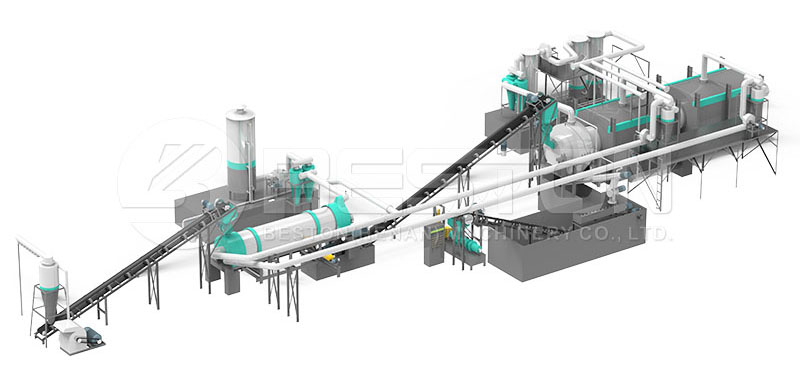

Operational Principle of Carbonization Plant

1. Gasifier equipment can produce fuel gas by heating the raw material

2. The gas fuel can be used by the carbonization stove to heat the raw materials.

3. The dust-removal device will remove the dust in the gas by the recycling water.

4. Gas cleaner will make gas clean, and you can use the gas to heat, which will not pollute the environment.

5. Cooling and discharging conveyor will cool the charcoal when discharging.

From the working principle we can know that the charcoal carbonization process is energy saving, because it can achieve self-sufficient during the working process, in addition, the emission can reach the national standard.

The sawdust charcoal making machine makes fully use of the biomass waste, and create new value, which is beneficial, thus it deserves the promotion and you can search the Internet for more information if you have an interest.