Statistics have shown that approximately 1 billion used tyres are produced each year across the globe; however, despite the recycling initiatives, only a small portion of these tyres are recycled. It is often the case that these tyres are either dumped illegally or sent to landfills instead of being recycled. The reason? It is just too much effort to complete the full recycling procedure and far simpler to dump the item. Unlike organic substances, a used tyre can take approximately 30,000 years to disintegrate and before disintegration it will act as a strong fire hazard. To overcome this problem, many governments are emphasising the act of recycling and are beginning to pass laws regarding the recycling of certain items. This article will provide information regarding the importance of recycling these items, as well as the method whereby they are recycled by waste tyre recycling pyrolysis plant.

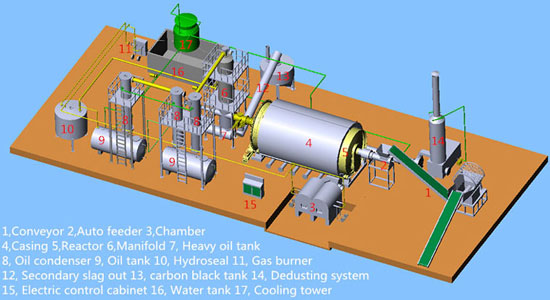

The most common means of tyre recycling is through a tyre pyrolysis process. The pyrolysis method involves the heating of both shredded and whole tyres by removing all oxygen when placed in a reactor vessel. The oxygen-free atmosphere of this vessel induces a melting of the tyre rubber and breaking down of this rubber into smaller molecules. The molecules are transformed into a vapor which exits the reactor vessel in the form of moving gas. Once the vapor has left the reactor vessel it can be burned to produce an oil type liquid that can be used as fuel. It should be noted that some of the molecules are too small to condense and will remain in a vapor state.

While the majority of these recycled tyres produce a form of oil, it is the properties of the original rubber that determines what type of liquid will be created. In addition to this, the compounds of the tyre will influence the type of heating conditions. For example, whole tyres are comprised of vulcanized rubber with large amounts of steel and carbon black. In order to decompose these high levels of steel and carbon one will be required to heat the item with directly fired fuel. The shredded tyre does not require direct fired fuel heating as it presents with a less amount of steel and carbon. An electrical induction or microwave heating is suitable for this type of tyre.

As with all recycling methods, the recycling of tyres via a pyrolysis process has various benefits. Firstly, pyrolysis methods reduce the amount of carbon emissions by melting the rubber using a temperature rising mechanism. Traditionally, the scrap tire recycling equipment would utilize high-sulphur coals to create a burning heat, which would contribute to high levels of carbon emission. Another benefit to consider is that the tyre recycling process reduces the accumulation of toxic waste. This is possible through the presentation of removable steel belts in the reactor vessel.

If you want to get more information about waste tires pyrolysis plants, please visit this webstie www.tyrepyrolysisplants.net.