There are many methods for extracting essential oils from plant materials, but one efficient is steam distillation. In this method, steam is passed through the plant material and picks up oil as it does. The steam is then condensed back into a liquid where the oil may be separated from the water.

One of the advantages of this essential oil extraction method is that it yields very pure oil. Other methods such as solvent extraction have the potential of yielding the oil that contains chemical by-products.

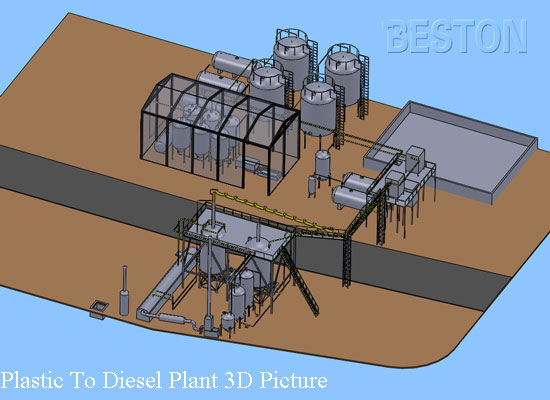

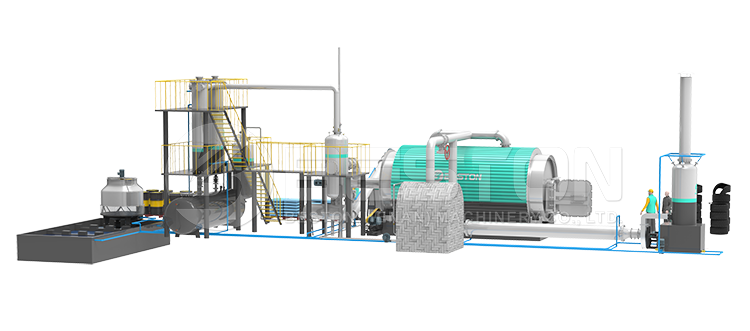

These days, everything is assessed by a quality and no extraordinary case for oil. Despite the way that they can have pyrolysis oil from plastic waste by plastic to diesel refining the oil may be connected with generators, it emits an impression of being gatherings of individuals may need to search for after higher quality oil, similar to diesel and fuel. In this manner, the refined oil changes into a to an extraordinary degree hot and exceedingly beneficial green task, which is sold low, collect grungy material successfully and adherent pyrolysis to diesel from oil or gas proficiently (oil recuperation rate is around 90%).

In hardly a second, different pyrolysis oil refining plant makers grow up after a spring precipitation. Affiliations being in the field for quite a while, oil refining machine gets exceedingly pushed advancement which is highlighted in broadening 5% oil yield, sparing 30% fuel utilization, securing the earth and guaranteeing 100% thriving. We have different types of the plant for sale now: www.bestonpyrolysisplant.com.

What’s justifying being said is that the things they have researched are fit for get prepared both refined oil by pyrolysis gear and a gathering of waste oil, for example, utilized motor oil, slag oil, grungy petroleum, foul petroleum, waste fuel oil et cetera. Here they’d like to present all the more no fuss data for you; there saw clients.

Astounding Advantages of Beston Distillation Plant:

* High time yield: the unpleasant material recuperation degree is around 90%. Precisely when the water substance is under 5%, the degree can even surpass 90%.

* High on-stream productivity without usage, fouling, and coking.

* Auto managing and slag releasing helps the waste plastic to diesel plant in completing consistent running for the entire day.

* Featured by environment confirmation operation tech and gadgets. During the system, water or soil or air contamination exists.

* The savviest diesel from oil refining advancement.

* It is direct the machine for refining to clean and stay mindful of a vertical structure.

* The system makes an option of centrality to supplant petroleum things and normal gas.

1. There is done gear organized regular insistence, like channel gas dust gathering room and waste gas burner.

2. Get central substance method: execute the shading and striking smell of things.

3. The utilized or waste oil refining machine can diminish the waste and settle the oil asset lessening issues.

4. The water stream advancement to discharge the greatness of the contraption can staggeringly enhance the safety of the system, in addition the yield and nature of the oil fuel.

5. The waste plastic to diesel refining plant gets a handle on the hot air warming improvement for the warming system, which can promise the security of system and augmentation the warming benefit.